- Muflas para Hornos

- Mufas para hornos horizontales

- Muflas para hornos verticales

- Muflas para hornos de campana

- Muffles para carburación de nitruración

- Muflas para hornos transportadores

- Muffles para galletas de amoniaco

¿Qué es el proceso de recocido brillante protegido con hidrógeno?

1、 Definition and principle of hydrogen protected bright annealing process

Hydrogen protected bright annealing is a commonly used technique in metal processing. Its main principle is to anneal metal materials at a certain temperature and in a hydrogen atmosphere. Through the reduction effect of hydrogen, the oxide content is reduced to improve the surface smoothness and mechanical properties of the metal.

2、 Application of hydrogen protected bright annealing

The hydrogen protected bright annealing process is widely used in the processing of metal materials such as stainless steel, steel, aluminum alloys, and copper alloys, especially in industries such as electroplating, spraying, and welding. Its effect is more significant than traditional flame annealing, high-temperature air annealing, and vacuum annealing methods.

3、 The advantages of hydrogen protected bright annealing

Compared with traditional annealing methods, hydrogen protected bright annealing has the following advantages:

Ensure the smoothness and quality of the metal surface, giving it better toughness and ductility.

It can effectively reduce the oxide content in metal materials, lower the electrochemical reaction of the passivation layer, and improve the corrosion resistance and anti-corrosion properties.

It can improve the mechanical properties and strength of metal materials, increase their service life and stability.

In summary, hydrogen protected bright annealing is an effective metal processing technology that has significant advantages in improving metal surface quality and mechanical properties. It will be widely applied in more fields in the future.

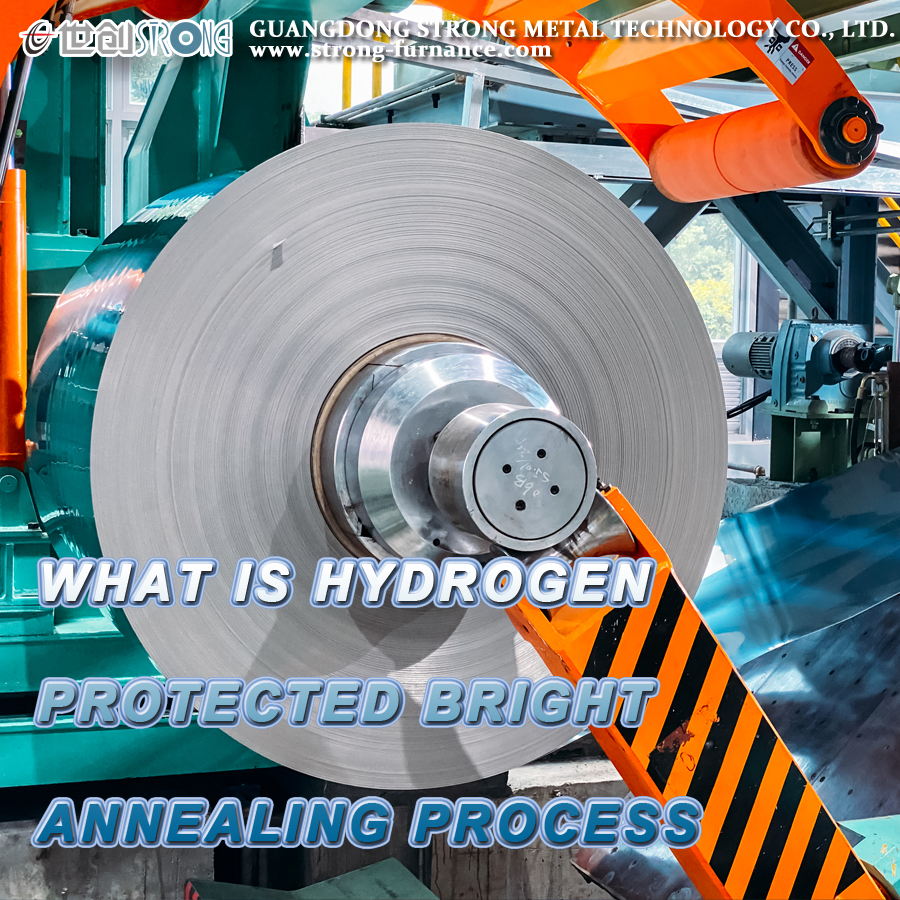

Strong Metal’s customized continuous stainless steel strip bright annealing line by hydrogen protected

Usage: Used for continuous bright annealing of stainless steel strips, plain steel, alloy steel, spring steel, copper, etc.

Thickness: 0.1~3MM

Width: 250~1450MM

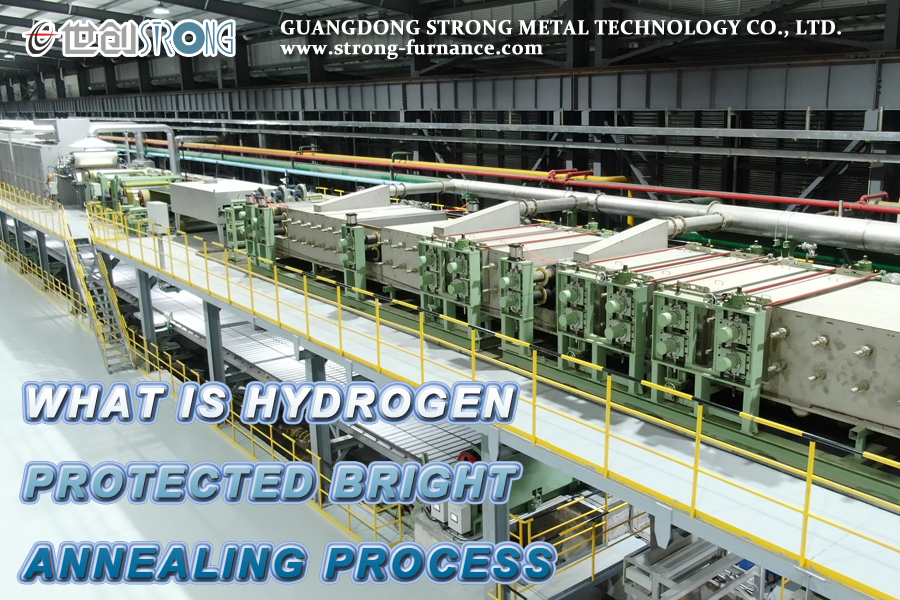

Natural gas (LNG), liquefied petroleum gas (LPG), and diesel can be selected as the main heating methods of the furnace.

The unit of the stainless steel strip bright annealing line consists of an inlet section, an inlet looper, a degreasing section, a process section, an outlet looper, and an outlet section.

It adopts automated control to form an ultra-highly integrated and precision-controlled line, realizing technological integration and innovation of stainless steel cold-rolled strip continuous lines.

Features: fast heating speed, low energy consumption, low cost, safe and reliable, high degree of automation and customizable.

Scope of application: widely used in metallurgy, special steel, and precision strip industries.